Protecting end customers from defects is critical in the manufacturing industry. Rising part and process complexities, tighter tolerances, shorter cycle times, and labor availability have made quality control inspections more important and challenging. More parts need to be checked, more frequently, without disrupting production.

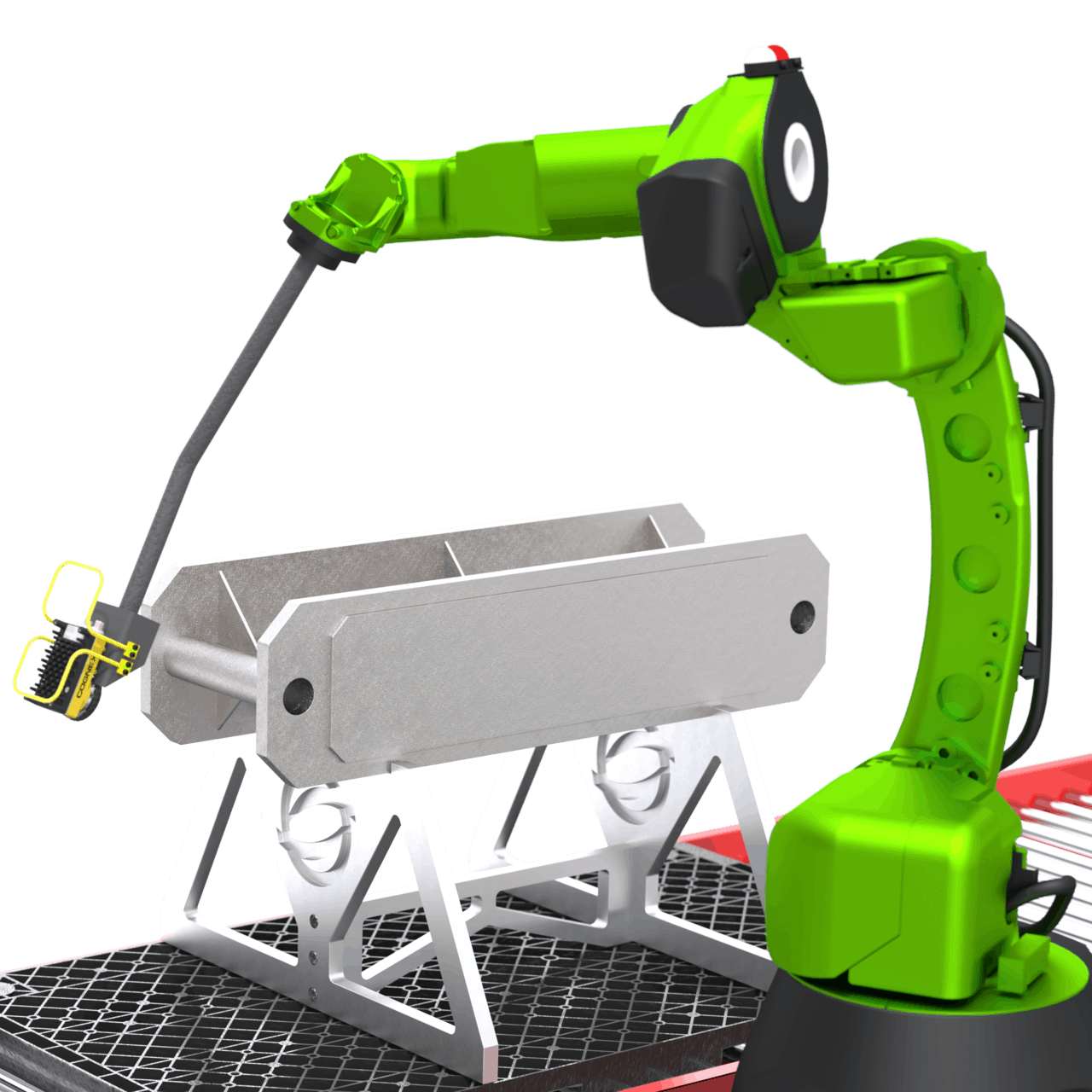

The I-CV is designed to complete multiple inspections with a single camera – even in areas that are difficult to access – to support a production line with reliable and accurate results. Its system is capable of automated inspection of various components for defect detection, option and assembly verification, and optical code recognition.

I-CV

Pre-Engineered Design for Low Cost & Quick Delivery

Easy to Deploy & Maintain

Operator Friendly

CSA & ANSI/A3 Safety Compliant Design

Training & Support

Supports up to 1 Camera

Supports up to 32 Acquisitions/Camera

Supports up to 16 Inspections/Acquisition

Parallel Image Acquisition & Processing

Communication: Ethernet/IP or Profinet

Input Power: 575V or 460V

FANUC CR-7iA/L Robot

Cognex 2MP 7802C Camera with Autofocus Module

End of Arm Tool (EOAT) with Foam Camera Case

Standard Robot Mount

Integrated Robot Control System (PMC)

Programming for 5 Average Inspections

Controls Training (3-Day BOS Curriculum)

Additional Inspections

BOS I-DV Upgrade

Part Fixture & Tooling

PLC Control System with HMI

Specialty Robot Mount (e.g. Inverted or Side-Mounted)

Custom EOAT

Line Tracking

Cobot Hand Guidance Tool

Upgraded Robot (e.g. CR-15iA for Longer Reach)

Additional Training

LEARN MORE ABOUT THE I-CV

Contact us today for more information, including pricing. We look forward to collaborating with you.