COLLABORATIVE ROBOT SOLUTIONS FOR MANUFACTURING

Imagine a world without safety barriers; a world in which humans work side by side with robots safely. In this world, the robots do all the strenuous repetitive work, freeing us up to use our brains and manual dexterity to do the lighter, more intricate jobs.

A collaborative robot, or cobot, is built to work safely alongside people to automate processes in factories or for other purposes. In the industrial world, cobots are great assistants to operators whose value is in the intricate work on the product.

Advanced technologies have allowed engineers and programmers to create these robots so they can react to human interaction while ensuring people’s safety. This is possible due to safety features, such as sensors, lightweight materials, rounded edges, and limited speed and force.

The collaborative robots can be used to lift objects, execute repetitive and dangerous handling tasks, assemble workpieces, and collaborate with several other manufacturing processes within various industries. Discover how automation can help your business.

Benefits of Collaborative Robots

Collaborative Robots can drive productivity

Opportunity to increase profitability

They can also improve ergonomics

Your business can become more exclusive

Unskilled tasks can be eliminated

Your company can become more competitive

BOS Cobot Solutions

BOS has what it takes to integrate customized solutions with collaborative robots for your specific needs. In fact, we were the first integrator to successfully install a FANUC cobot in Ontario. Below are a couple of examples of where this technology has helped manufacturers.

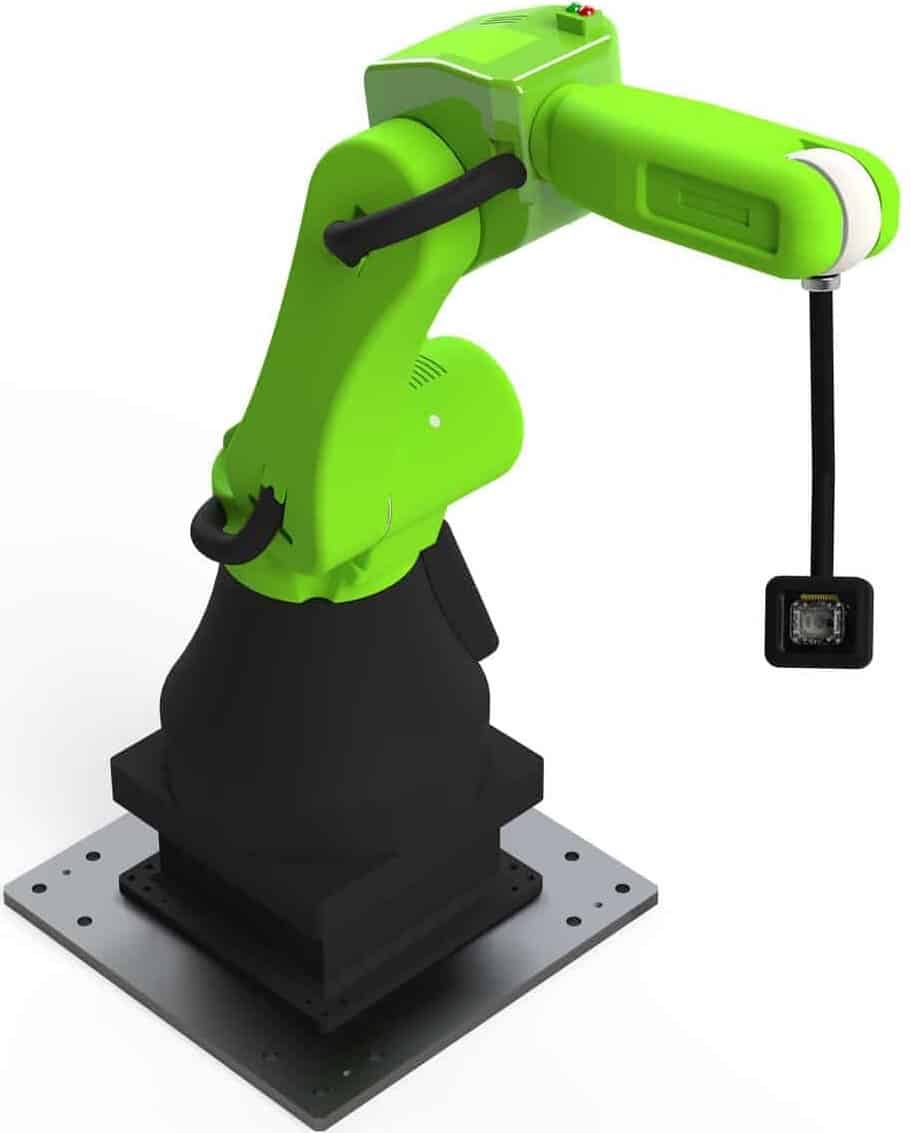

Quality Control Assistant Robot

Collaborative robots can be a great asset in following the operations of the human to check and assure the quality of the operations. Arm your cobot with a camera, laser sensors, electrical test equipment, and probes to efficiently and safely test the parts in the same spot it was assembled with an operator.

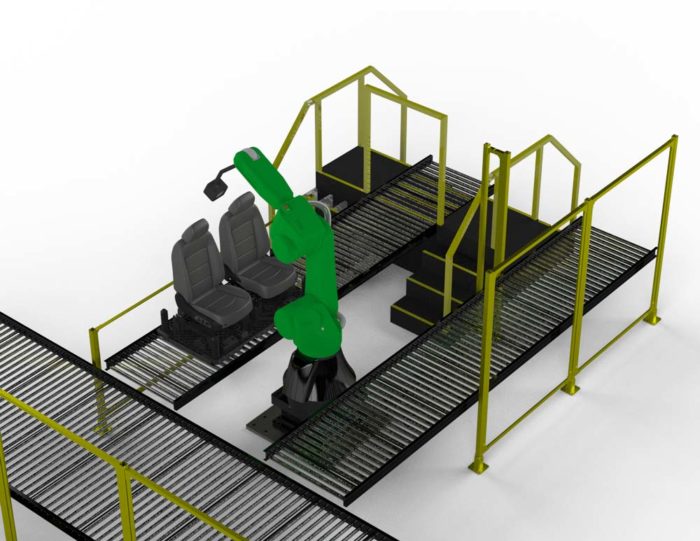

Ergonomic Operator Assistant Robot

Preventing the risk of repetitive strain injuries amongst assembly line workers while improving productivity is a great reason to consider collaborative robots. Cobots can lift and position components for you, or provide a smart and adaptable lift assist when guided by the operator for part of the sequence while automating the rest of the sequence.

Advanced Manufacturing Solutions

Not sure where to begin? We have proven, modular designs to help get you started. If you need something a bit different, no problem, our experts are available to customize it just for you.

Check out our cobot vision inspection solution (I-CV):

FANUC Collaborative Robots

BOS Innovations is a certified integrator of FANUC CR series. Offering payloads of 4 kg, 7 kg, 10 kg, 14 kg, 15 kg and 35 kg and unrivaled reach, this product line is ideally suited to handling processes that expose people to the risk of repetitive strain and other work-related injuries. Precise and repeatable, they also offer you huge benefits in terms of quality and throughput. Learn more about the Collaborative Robot Lineup from FANUC.

LEARN MORE ABOUT AUTOMATION

Contact us today and see how we can help you automate your business.